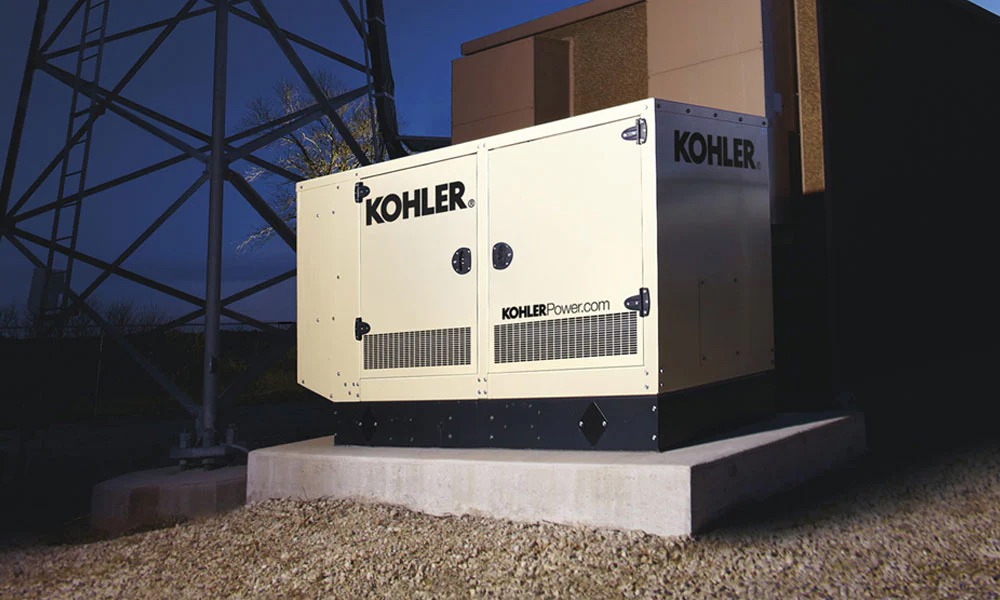

Hydrotreated vegetable oil can provide a more sustainable alternative to fossil fuels for mission-critical power generators in applications such as data centers and hospitals across southeast Asia.

There is growing interest across southeast Asia in the use of an exciting renewable fuel for mission-critical power generation that delivers significant environmental benefits compared with conventional fossil-fuel-derived diesel.

Hydrotreated vegetable oil (HVO) is made from waste products and residues such as vegetable oils, animal fats, and used cooking oils. It is 100% fossil-free and 100% recycled. Since it is obtained from organic material from waste streams, HVO — unlike many first-generation biodiesels — does not contribute to deforestation.

The technical and performance characteristics of HVO mean it is becoming increasingly popular as a sustainable alternative to fossil diesel for mission-critical power. For applications such as generators, HVO can reduce net carbon emissions by up to 90% compared to fossil diesel, while also delivering a 10% reduction in NOx.

DATA CENTER AND HEALTHCARE APPLICATIONS

Recently, Kohler announced that its entire offering of mission-critical diesel generators was compatible with HVO. That move has prompted a surge of interest across southeast Asia, with mission-critical power users in countries such as Indonesia, Taiwan, Singapore and Thailand showing an interest in the renewable fuel. These early-stage users are primarily considering HVO as a sustainable solution for advanced data center generators such as the KD Series, which maintain continuity of power over extended periods when there is an electricity outage from the grid.

However, other applications are increasingly coming to the fore. For example, healthcare facilities such as hospitals also require emergency backup during grid failure. And the location of these facilities – often in dense metropolitan areas – means there is a growing need to generate this power while minimizing greenhouse gases in the local environment. HVO provides a superior, cleaner-burn than existing fuels and that feeds through into fewer emissions across its lifecycle.

But what factors might prevent healthcare facilities from adopting HVO across southeast Asia? Firstly, there have been concerns about the availability of the fuel – particularly in more remote locations. However, multi-million-dollar investments are being made in the global supply chain, and HVO is becoming more readily available.

New and expanded production facilities have recently been announced in Singapore and Malaysia, and many other plants are in the pipeline. More local supply of HVO – closer to the end-user – means reductions in carbon emissions usually associated with transportation. Using waste feedstocks encourages shorter supply chains than first-generation biodiesels, which rely on raw materials shipped worldwide. Furthermore, HVO is only likely to be used for backup power in healthcare facilities such as hospitals – meaning only low volumes will be required.

The second concern is the ability to mix HVO with conventional fossil-fuel-derived diesel. However, the HVO production process ensures that the final product is similar in grade and quality to fossil diesel. It can be used as a drop-in for existing infrastructure without modification or impact on maintenance schedules. It is entirely compatible with the standard mix of fossil diesel fuels. Therefore, it can also be blended with fossil diesel – boosting flexibility for the end-user.

HVO IS POWERING THE FUTURE

Ultimately, there are no downsides to using HVO in mission-critical applications. It has proven its worth as a renewable fuel in data centers, with healthcare facilities now following suit. As the supply chain matures, it could also find use in other settings, such as airports, where more sustainable operations are seen as desirable.

In short, HVO provides plenty of options in southeast Asia. Its environmental credentials support the use of today’s generators for tomorrow’s generation.