How to maintain your power generators

Electricity is an essential component of our industrial revolutions and an enabler for almost every aspect of our lives. From the lighting that brightens our homes at night to the various IoT (Internet of Things) applications powering our smart homes, everything is driven by electricity. The key to this constant supply of power is power generators.

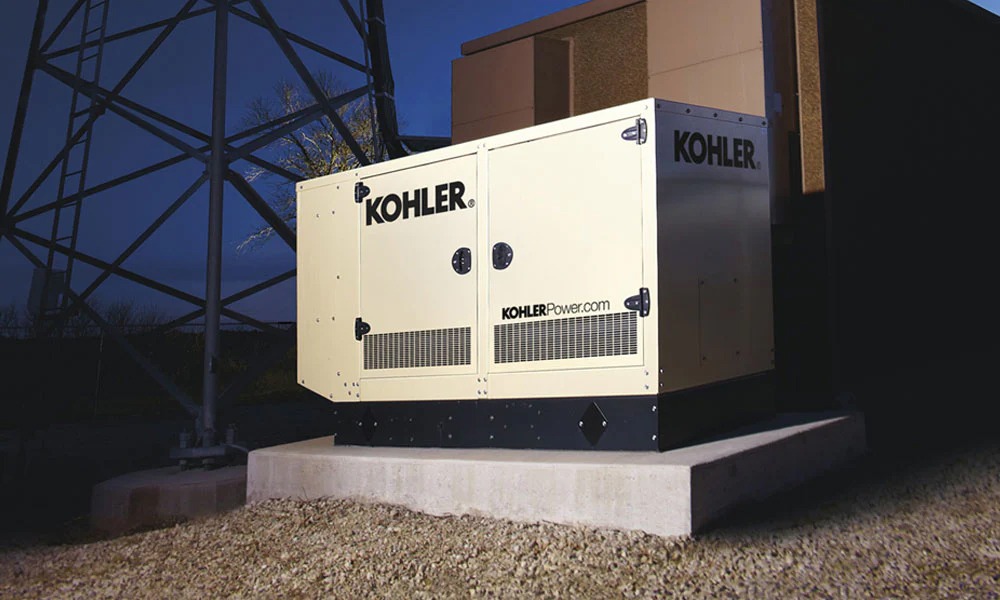

Of course, the electricity supplied to our homes and offices comes from the energy grid. However, that does not mean we have no need for power generators in our day-to-day lives. In fact, standby generators are wonderfully unappreciated machinery. As a backup solution to the energy grid, you won’t see them operating normally. However, you will not want them to malfunction either during an emergency.

That is why it is essential for you to maintain your industrial generators regularly to ensure they are working perfectly when called upon. Let us cover the essential points of maintaining your power generators.

The Importance Of Maintaining Your Generator Regularly

As more and more industries, such as data centers, hospitals, and remote areas, require generators for backup power, higher-performing generators featuring high power density and low fuel consumption and emissions are in constant demand. However, the equipment that caters to these applications requires regular maintenance to perform optimally.

Just as we require regular health checkups, these generators need daily, weekly, and monthly inspections to ensure they remain in tip-top condition. The frequency of maintenance depends on various factors.

Firstly, using inferior-quality engine oils, coolants, or diesel fuels can affect the lifespan of your equipment. While your generator can still function, the parts will likely need replacing sooner rather than later to prevent your equipment from malfunctioning. After all, your generator can only run as well and as long as its weakest link. We recommend implementing a complete maintenance program, from conducting daily checks to scheduling yearly part replacements, to ensure it remains in tip-top condition.

Another factor is the environment. For instance, you will need the correct generator set-up for specific work locations. For mining environments where the atmosphere is dustier, heavy-duty air filters will need to be implemented. Conversely, generators situated in more humid or damp surroundings will require additional fuel-water separators.

Meanwhile, marine generators or those situated close to the sea will require additional maintenance due to the more caustic surroundings. In particular, the sacrificial anode rods of marine generators will need to be inspected and replaced regularly to prevent damage to the equipment.

Additionally, we recommend turning on your generators and operating them for a few minutes each week. Doing so will ensure the generator is lubricated properly and allow you to spot any abnormalities before they snowball into a bigger issue down the road. When it comes to maintaining your power generators, the more you upkeep your equipment, the fewer issues and less downtime you will encounter. Remember, it pays off in the long run to conduct proper maintenance frequently.

How To Maintain Your Generators Correctly

When maintaining your industrial generators, always start with the most important component – the engine. We recommend referring to the engine operations manual and generator maintenance manual for details and adhering to the strict instructions provided to ensure a seamless, error-free process.

It is also advisable to have standby electrical components, such as sensors, controllers, injectors, and more, readily available in case there is a need to replace a faulty part urgently. To better understand what components require prompt attention and replacement, run a diagnostic test on your equipment.

You should also have brand-new filters on standby as well since you are encouraged to replace them in the event any are removed. Remember to use genuine replacement parts sourced from reliable manufacturers only! Not only are these components tested and guaranteed to work with your generators, thereby reducing failure and time spent troubleshooting your equipment, but they can also reduce costs in the long run.

Lastly, always refuel the engine with high-quality petroleum, oils, and lubricants (POL). Poor-quality fuels often contain impurities and contaminants that can wear out injectors and pumps prematurely, reducing overall equipment reliability.

Choose The Correct Personnel To Maintain Your Generators

The personnel maintaining your industrial generators should always be trained professionals familiar with the equipment on hand. Ensure they have the proper specialized tools on hand to enable a seamless diagnosis, allowing you to identify the root cause plaguing your generator quickly and accurately. Utilizing the right maintenance program will also reduce the chances of failure on the generators.

When Should You Maintain Your Generators?

Now that you have a better understanding of how to maintain your generators, you might be wondering what the optimal maintenance schedule is. The answer to this question is always, “before any trouble occurs”!

However, it is impossible to predict when an issue might crop up. Moreover, due to the perceived hassle of maintaining the equipment, many owners often neglect or overlook the importance of scheduling a technician to inspect their generators.

Some might even try to cut corners by reusing filters or delaying maintenance for several months. Conversely, others might not even think of upkeeping their generators until problems emerge or during an emergency, such as the unexpected shutdown of the power grid.

While these decisions might seem like genuine cost-cutting measures at first glance, you could face extended downtimes and higher expenses when you finally get around to maintaining your generators since more time and effort are necessary to upkeep equipment that has not been in use for a prolonged period.

So, as you can see, it is essential to conduct daily, weekly, monthly, and yearly checks on your active standby generators. If you want to minimize the time spent on inspections, you can consider using better-quality POLs. Not only do they offer peace of mind. They also contribute to substantial cost savings long-term by reducing the frequency of upkeeping your equipment.

We also recommend taking lab samples of the lubricants. Doing so can help you better understand the condition of your generators. If an abnormality is detected in the samples, it may suggest a more thorough investigation is necessary to identify and rectify any potential underlying issues.

If you plan on storing your generators away for a period longer than 6 months, additional storage steps must be undertaken to preserve the state of your equipment. Extensive maintenance work, such as the pumping of anti-corrosive preservatives to prevent corrosion and regular manual cranking of the unit to maintain lubrication, is necessary to get them up and running smoothly again. When the time comes to boot up your generators, the preservative fluids must be drained and replaced once more with coolant.

Where Should Maintenance Be Done?

The majority of the time, maintenance should be done onsite, whether it is on a boat, in the generator room of a building, or as part of an array of generators in a data center. With that in mind, having the correct set-up for maintenance will definitely aid the upkeeping process and the subsequent testing procedure.

For ease of maintenance, we recommend having lifting equipment onsite to hoist any heavy components necessary for repair work. Additionally, ensure there is sufficient space between each generator to allow the technicians to carry out their jobs safely. Having load banks onsite will also help speed up the testing process since you do not have to bring in rental load banks or resort to building loads.

Lastly, it is wise to have contingency plans in place in case an overhaul of the generators is required to significantly reduce downtime. Often, property is erected around the generators, making it challenging for technicians to access and replace them with brand-new equipment.

Conclusion

As you can see, regular maintenance is vital to keeping your generators in the pink of health. Keep what we shared in mind, and you can ensure your equipment will continue operating seamlessly for years to come!

If you are looking for quality components that meet the highest standards for operation and durability, look no further than Rehlko to meet your maintenance needs.

Alvin Lin

He is an Aftermarket & Service Training Senior Engineer with Kohler Power Systems. He has been with Kohler since 2016 and supports South-East Asia regionally. He has a wealth of hands-on & troubleshooting experience with power generators and large diesel engines, specialising in Kohler KD Series Engines.